Project

Juliet & Minke

- SECTOR: Decommissioning, Oil & Gas

Project Overview

Project Info

- Date 14/10/2019 – 26/10/2019

- Site Juliet & Minke

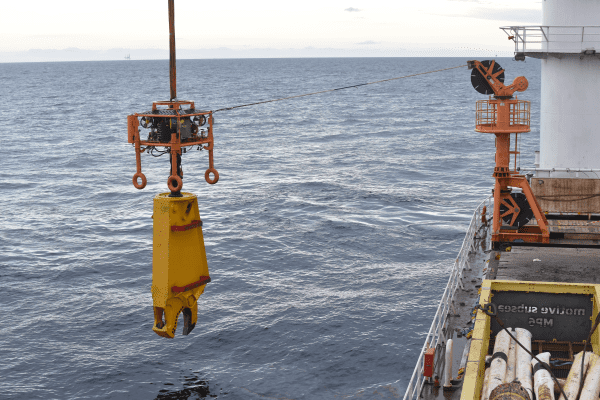

- Vessel Ocean Yield Connector

- Operations Asset De-Burial, Mattress Recovery, Product Cutting, Debris Removal, Burial of Exposed Pipeline Ends

- UTROV® Tooling Used Clamshell Grab, Controlled Flow Excavator, Tine Grab, Mattress Recovery Tool, Shear Cutter, Pipe Grab.

Utility ROV Services were contracted by Boskalis Subsea to aid with decommissioning works on Neptune Energy E&P UK’s Juliet and Minke fields. The work scope consisted of the following; de-burial of assets, recovery of concrete mattresses, cutting and recovery of pipeline, spools & flexibles, clearance of debris and burial of exposed pipeline ends – all in 40-60 metres of water.

Operations were conducted from the DP3 vessel, Ocean Yield Connector, from which Boskalis conducted the full decommissioning work scope.

Utility ROV Services performed five main operations during this project at two separate sites:

- Asset De-burial

- Mattress Recovery

- Cut and Recovery/Relocation of Pipeline, Spools & Flexibles

- Grout Bag and Debris Recovery

- Burial of Exposed Pipeline Ends

Initially, the Controlled Flow Excavator (CFE) was used prior to recovery operations to clear sediment and aid identification of the assets for recovery.

Following CFE, the Mattress Recovery Tool (MRT) was utilised to deal with a variety of simple and complex recovery scenarios. This included overlapped, folded or mattresses suspended over pipelines. The integrity of each mattress was relatively unknown, allowing the MRT to prove its capability where the 8-year-old mattresses showed significant integrity issues and would be irrecoverable using their rope loops. Most mattresses were recoverable to surface using the MRT, however where mattress integrity determined this unfeasible, mattresses were placed into subsea baskets by the MRT. The adaptability of the MRT further proved the tool as a hugely successful innovation in decommissioning technology.

The next phase of operations called for the UTROV® to be fitted with the Shear Cutter to allow the cut and recovery of 85 metres of 12-inch pipeline at Juliet and 75 metres of 8-inch pipeline at Minke. Once cut, ten-metre sections were then relocated into baskets subsea using the UTROV® & Shear.

To support debris & grout bag recovery operation, the UTROV® was equipped with the Tine Grab. Grout bags were placed into baskets subsea or recovered to a basket on deck.

The final phase for the UTROV® & Tine Grab was to spot cover the exposed umbilical and pipeline ends with rock dump taken from excess around the worksite.